The Laboratory Notes of Thomas Edison

Leading to his invention and perfection of the alkaline storage battery. With four original-issue printed patents.

At the turn of the 20th century, Edison saw the enormous future potential in storage batteries, yet was impressed with what he considered the serious inherent defects in batteries of the day, which were made with lead. He determined boldly that he would devise a battery without lead, one in which...

At the turn of the 20th century, Edison saw the enormous future potential in storage batteries, yet was impressed with what he considered the serious inherent defects in batteries of the day, which were made with lead. He determined boldly that he would devise a battery without lead, one in which an alkaline solution could be used- a form which would, he firmly believed, be inherently less subject to decay and dissolution than the standard type.

Starting about 1900, Edison put together a staff of engineers and scientists knowledgible in the necessary fields of chemistry and metallurgy. They initially attempted employment of copper oxide as an element in a new type of storage cell. Its use turned out to offer no advantages, and the hunt was continued in other directions. Finally, after a vast number of experiments, Edison found that nickel and iron possessed the qualities he sought. He then faced the necessity of obtaining the best and purest compounds for active materials. He found that comparatively little was known by manufacturing chemists about nickel and iron oxides of the high grade and purity he required, so he established his own chemical works and put it in charge of men he specially trained. His team included people like Ignacy Goldstein, Peter Christensen, Louis and John Ott, Walter Holland and John W. Lystrop. They conducted innumerable experiments to develop the various chemical forms of nickel and iron, and to determine by tests what would be best adapted for use in cells manufactured on a commercial scale.

As Edison's idea developed, his storage battery would be composed of perforated metallic containers having the active materials packed in; nickel hydrate for the positive plate and iron oxide for the negative. The difficulty of obtaining good electrical contact in the positive element was Edison's chief trouble and required a great amount of work and experimentation before he decided on a form of graphite. The size and shape of the containing pockets in the battery plates or elements and the degree of their perforation were also matters that received many years of close study and experiment. His battery concept proved successful in 1910, and building on this achievement, improvements were made over the course of another decade.

John W. Lystrup was a chemical engineer who spent many years working in Edison’s laboratory for his Edison Storage Battery Co. The Edison Papers records him as “John W. Lysthrup.” He retained the notes Edison sent him containing detailed instructions about the experiments to perfect the battery; some of them have Lystrup's notations at the bottom showing what he did in response. Most of them were written 1906- ca. 1910. Lystrup later placed the notes in a scrapbook along with some printed images, pictures, and letters. We acquired the group from Lystrup's great-grandson; it has never been offered before.

Exerpts from Edison’s notes:

1. Autograph Letter Signed “Edison” on The Tropical Winter Resort of the West Coast letterhead, Fort Myers, Fla., April 1, 1906. “Did you get my note saying that if you have any more of the 734 containing 16.8% Bismuth to put up one tube without any flakes.”

2. Autograph Note listing elements being tested, including sulphate cadmium, cobalt and uranium, among others. He writes at bottom, “Crystalized.” Lystrup has dated the note July 22, 1907.

3. Autograph Note Signed “E”, saying “You haven't sent me any tubesÉwith flake that has different percentages of aubydrom and bismuth, & also metal, is the delay on account of lack of cans. Don’t see how that can be.” Lystrup notes that he has relied to this in a report sent to Edison at Fort Myers.

4. Autograph Note Signed “E.” “OK, done. Don’t forget to put up Goldstein's tubes containing bismuth. There are 44 of them…” Below that, Lystrup notes “42 of these reached over 1200 amps, rest dipped below 900.” They are also using marble, as Edison says “two tubes 854 mixed with 5% crushed marble,” and adds “Christensen can give you some nice white marble…”

5. Autograph Letter Signed “E.” “If you will double the usual amount of bags over each crock & keep them at work always. I will make 6 to 10 new baths daily so you can remove each day say 10 old ones & put in 10 new ones with sight feed…What about it = Don't want to do anything until I am sure the scums have been eliminated by filter bagsÉ”

6. Autograph Note, “Should at 14.8 average amp at 8 3/4 to qv. Give 710 amp hours. It takes 13 amp hours to each 1/1000 thick. It should have callepered .054.65 instead of 48. Failed to regulate.” With Lystrup's note on bottom “OK.”

7. Autograph Note Signed “E.” “Load iron mix into nickel tubes same as you would load nickel, & set each tube up with 4 nickel tubes. Call Holland’s attention to them. Be sure and clean the machine thoroughly of Iron when you finish.” With Lystrup's note on bottom, “Made two tubes without flake, ditto with flake.”

8. Autograph Note with a long list of elements at the bottom, crossed off as they were tried in experiments, with three circled (tantalium, zinconium and selenium), perhaps because they were promising. “2 in a group…2 grammes of following metals metalically connected to each tube…see Louis Ott about getting the metals…”

9. Autograph Note Signed, “Edison.””Test cells show that the smoother the inside of the tube the greater the capacity per gram of nickel green. Make up 1/2 dozen tubes with stock rolled out…make up 2 tubes of each kind – Load with 854…flake and tamp.”

10. Autograph Note Signed “E.” “Have you any more of the green that has 16.8% of Bismuth in it. If so put up 3 cells…” Lystrup's note on bottom in parenthesis “(on rack #2É).”

11. Autograph Note Signed “Edison.” “Also Duplicate all the above & in addition put 2 grams Bismuth connected with each tube. Each tube in this case will have the special metal & all will have Bismuth in addition.” Lystrup lists at bottom 20 metals, with results of each (eg. “Tin=3503-04A. BiÉ”).

12. Autograph Note written on graph paper, with drawings. “Never wash tops of bath until nickel or coppers have been in several hours.”

13. Autograph Note Signed “E.” “How does these pass inspectors & go up stairs & have center soldered on when they are so defective.”

14. Autograph Note Signed “E.” “I forgot to state about the rolled tube stock that the rolling should be done before it is nickel plated…You might try pressing as well as rolling – don’t roll the stock down too thin.”

15. Autograph Note Signed “Edison.” “Special Row—Experiment…When they are stripped & go up stairs for turning face each should be callipered when finished, OK. We want to find out how they finish up…This lot started bad, had 11 1/2 volts on & entirely too much current.” Lystrup writes, “11 1/2 volts must be maintainedÉ”

16. Autograph Note Signed “Edison,” March 1, 1910. “Take some regular green & expose it to air in the galoenometer room where there is no dust…Mix it up well each time…& send reports.”

17. Typed Letter Signed “Edison” on Laboratory of Thomas A. Edison letterhead, Orange, N.J., June 16, 1917, to Lystrup. “Accept my warm appreciation for your efforts in obtaining the very handsome subscription to the Liberty Loan. Also extend this appreciation to all subscribers in your Department for their patriotism and sacrifice in meeting the payments for the Bonds, which I trust you will facilitate with the Banks in the same spirit of cooperation.” The signature appears to be in both ink and pencil, so one or the other may have been traced over.

18. Autograph Letter Signed “Edison,” August 6, 1920, 3 pages. “Lystrup – Do not put in Acetic acid in your nickel baths as long as the baths turn Blue Litmus paper perfectly red. Do not put in nickel hydroxide until your copper goes to 20 milligrammes per liter… at present your copper is very low only about 8 milgms per liter and there is no need of putting in nickel hydroxide until it gets near 20 milgms per liter…When your litmus don’t turn a full red add regular amount of acetic acid.”

19. Autograph Note Signed “Thos. A. Edison,” August 9, 1920. “Temperatures of wax master baths are to be kept at 70û Fahr hereafter-” With Lystrup's note on bottom in red, “This was raised to 74û 8/20-1920.”

Also included in this group are four scarce printed patents from the United States Patent Office, each containing figures and detailed descriptions of how the invention works and why it is of value; all are signed by Lystrup on their covers. Edison received 147 patents concerning batteries; these four are: No. 936.443. “Tube Filling and Tamping Machine. Application filed October 14, 1905. Patented Oct. 12, 1909.” This patent features sixteen figures with numbered parts. “Be it known that I, Thomas A. Edison, a citizen of the United States…have invented certain new and useful Improvements in Tube Filling and Tamping Machines…My invention relates to an improved machine or apparatus which has been designed particularly for the purpose of automatically filling and tamping active material into small perforated tubes…”

No. 1.115.463. “Electrode Element. Application filed June 17, 1910. Patented Oct. 27, 1914.” This patent features six figures each with numbered parts. “Be it known that I, Thomas A. Edison, a citizen of the United States…have invented certain new and useful Improvements in the Electrode Elements…My invention relates to electrodes for storage batteries, to a process of loading the same with active material…”

No. 1.198.426. “Production of Electrode Elements. Application filed Aug. 31, 1914. Patented Sept. 19, 1916.” This patent features 6 figures each with numbered parts. “Be it known that I, Thomas A. Edison, a citizen of the United States…have invented certain new and useful Improvements in the Production of Electrode Elements…My invention related to the production of electrode elements for storage batteries and more especially to a process for making the same…My prior application…of which this application is a division, contains claims on the improved electrode element produced by the process forming the subject matter of this application…”

No. 1.311,955. “Tube Filling and Tamping Machine. Application filed Mar. 6, 1916. Patented Aug. 5, 1919” This patent features seven figures each with numbered parts. “Be it known that I, Thomas A. Edison, a citizen of the United States…have invented certain new and useful Improvements in the Tube Filling and Tamping Machines…My improved machine or apparatus has been designed and perfected particularly for the purpose of carrying on in an improved manner the automatic filling and tamping of active material into small perforated tubes…” This significant archive of Edison material is the first such grouping we have had, and it comes with the best possible provenance.

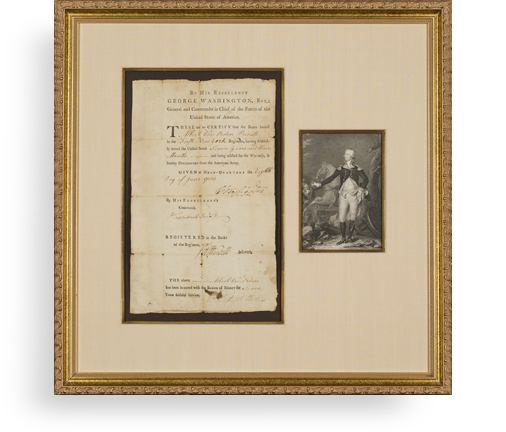

Frame, Display, Preserve

Each frame is custom constructed, using only proper museum archival materials. This includes:The finest frames, tailored to match the document you have chosen. These can period style, antiqued, gilded, wood, etc. Fabric mats, including silk and satin, as well as museum mat board with hand painted bevels. Attachment of the document to the matting to ensure its protection. This "hinging" is done according to archival standards. Protective "glass," or Tru Vue Optium Acrylic glazing, which is shatter resistant, 99% UV protective, and anti-reflective. You benefit from our decades of experience in designing and creating beautiful, compelling, and protective framed historical documents.

Learn more about our Framing Services