Thomas Edison Announces the Principle By Which He Would Ensure Safe Laying of the Wires Lighting New York City

“One thing is certain and that is everything must be poured in layers not only the boxes but the tubes.”

- Currency:

- USD

- GBP

- JPY

- EUR

- CNY

He is also close to a method of safely powering his electric generators or dynamos: “Regarding the paper for Dynamos we are trying a set of elaborate experiments, which will be finished next week. So far we find paper should soak 10 days then air dried in closed place and then re-dipped...

He is also close to a method of safely powering his electric generators or dynamos: “Regarding the paper for Dynamos we are trying a set of elaborate experiments, which will be finished next week. So far we find paper should soak 10 days then air dried in closed place and then re-dipped for a moment only and re-dried. Its like glass and spark does not go through.”

Thomas Edison propelled the world out of the gaslight era and into the electric age. With dreams of lighting up entire cites, Edison lined up financial backing, assembled a group of brilliant scientists and technicians, and applied his genius to the challenge of creating an effective and affordable electric lamp. With unflagging determination, he and his team tried out thousands of possibilities, convinced that every failure brought them one step closer to success. They succeeded where so many others had failed. On January 27, 1880, just a month after exhibiting his invention, Edison received the historic patent embodying the principles of his incandescent lamp that paved the way for the universal domestic use of electric light.

This changed the way everyone lived. Work could start early or continue past dusk. The evenings could be times of activity and recreation. The day no longer had to be confined to daylight hours or time huddled around the heat and light of the fire. It remains among the greatest advancements of the modern age. But a light bulb without a system of electricity delivery would remain nothing more than a lab experiment.

John Kruesi had been apprenticed as a locksmith in Switzerland, and migrated to the United States where he settled in Newark, New Jersey. There he met Thomas Edison, who was impressed with the young Swiss immigrant and took a liking to him, employing him in his workshop starting in 1872. He became Edison’s head machinist through his Newark and Menlo Park periods, responsible for translating Edison’s numerous rough sketches into working devices. Since constructing and testing models was central to Edison’s method of inventing, Kruesi’s skill in doing this was critical to Edison’s success as an inventor. Historians Robert Friedel and Paul Israel summed up Kruesi’s remarkable ability:

“If the devices that emerged [from Kruesi’s workshop] didn’t work, it was because they were bad ideas, not because they were badly made. And when the ideas were good, as in the case of the phonograph, the product of Kruesi’s shop would prove it.” Kruesi was involved in many of Edison’s key inventions, including the quadruplex telegraph, the carbon microphone, phonograph, incandescent light bulb and system of electric lighting. Kruesi was particularly proud of building the first phonograph.

Inventing a light bulb did not bring it into the home. You had to have a way to deliver the electricity needed to light the bulb. So Edison set to work creating a system to light the world. W.S. Andrews, one of Edison’s first employees, describes the system in great detail. “In 1880, Mr. Edison laid out a system of underground distribution.. from his laboratory in Menlo Park, to supply 1000 lamps, placed on wooden lamp-posts along the streets and roads of the village of Menlo Park and also in the dwellings. As no electric circuits had ever before been placed underground, there was absolutely no experience to guide in the proper laying and insulation of the conductors…” Conductors “were composed of No. 10 BWG copper wire… the system was a simple two conductor, multiple circuit… After a few weeks of experiments, the best of the insulating compounds was selected for use. This compound was composed of refined Trinidad asphaltum, mixed with oxidized linseed oil to give it the right consistency, and a little paraffine and beeswax were added to make the material smoother.”

The test was a success. Now came lighting New York City. A franchise having been obtained from the city, the work of laying the underground cable began in the late fall of 1881. That completed, in the summer of 1887, as the Edison Papers notes, Edison and his Electric Illuminating Company received permission to expand New York’s lighting into a second district in Manhattan’s Union Square district.

Edison was dissatisfied with the insulation of the conductors to be used on the project, which he bewailed as inadequate. It allowed bubbles to leak up through holes, which could cause electrocution. This was thus an issue of safety, and such potential leaks undermined the safety of his invention and complicated his project in New York. In late summer of 1887, as he began the hugely important New York project, he and his team worked diligently on solving the insulation problem on time to use the solution in that project.

Kruesi had a standard compound that he used as insulation. As the Edison Papers notes, Kruesi’s standard compound performed well on bare copper rods but failed when applied over metal wrapped in cotton. Edison concluded that when the insulation was applied to a surface that was not clean or perfectly dry “or on surfaces covered with material which the heat of the Compound turns into gas, we shall have Microscopic Vent holes invisible to the naked Eye” (an analysis similar to his observation in 1879 of destructive gas pockets in metal lamp filaments). On August 24, 1887, Edison noted that tests of compounds at the lamp factory laboratory showed that “if you can pour compound at 300 Fahrenheit it will be better than at higher temperature as when very hot it gives off too much gas.”

The issue of insulation was present also in Edison’s generators that were powering his system of lighting. His generators (or dynamos) were built with an armature core of about 1000 thin plates of soft wrought iron, insulated from the shaft, and separated by paper from one another. They were held between two end plates, one of which was secured by a washer shrunk on the shaft, and the other by a screw-nut and lock-nut. This paper was the source of the internal insulation.

Autograph letter signed, 2 pages, Orange, NJ, August 29, 1887. “Dear Kruesi, There is nothing the matter with your present compound. It is splendid. The whole trouble is air bubbles. The hotter it is poured the greater the amount of air bubbles at 212. It can be put on rods and there is no bubbles. I have a man experimenting and testing all the time. Until I get at the proper method of pouring and getting rid of the air bubbles, it will be a waste of time to experiment with other asphalts. Resin oil distills off easily. It may answer but parafine or other similar substance must be put in to prevent brittleness. One thing is certain and that is everything must be poured in layers not only the boxes but the tubes. The tube itself should have a thin coating. The rope should also have a coating. The rods also the whole of rods and rope when ready for tube should have another coat and then placed in tube and filled. This will do the business.

“Regarding the paper for Dynamos we are trying a set of elaborate experiments, which will be finished next week. So far we find paper should soak 10 days then air dried in closed place and then redipped for a moment only and re-dried. Its like glass and spark does not go through. The moment we are ready and know what to do, I will arrange to make you a big supply in the brick shop at Menlo Park.”

Here we see Edison’s practical yet inventive brain at work, always seeking a better way to refine his landmark inventions, while at the same time showing how he worked with his chief machinist to engineer the results and safely light New York.

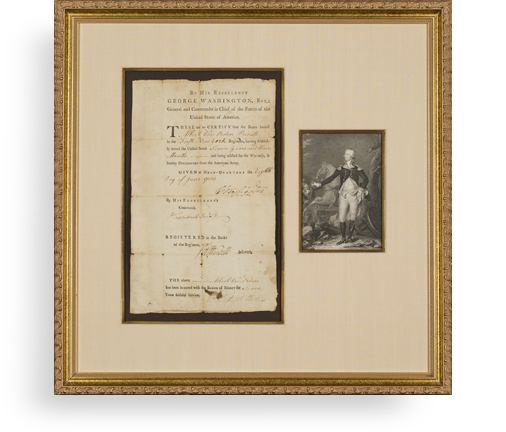

Letters of Edison directly relating to his inventions, written at the time of the inventions themselves, are incredibly uncommon. We acquired this directly from a Kruesi descendant, and it has never before before been offered for sale. It is interesting to note that no letters from Edison to Kruesi whatever have reached the public sale market in at least 40 years, nor can we recall seeing any.

Frame, Display, Preserve

Each frame is custom constructed, using only proper museum archival materials. This includes:The finest frames, tailored to match the document you have chosen. These can period style, antiqued, gilded, wood, etc. Fabric mats, including silk and satin, as well as museum mat board with hand painted bevels. Attachment of the document to the matting to ensure its protection. This "hinging" is done according to archival standards. Protective "glass," or Tru Vue Optium Acrylic glazing, which is shatter resistant, 99% UV protective, and anti-reflective. You benefit from our decades of experience in designing and creating beautiful, compelling, and protective framed historical documents.

Learn more about our Framing Services