The Legendary Paul Revere Works to Create a Professional US Navy Capable of Defeating Its European Counterparts

He writes the designer of America's first Navy, Joshua Humphreys, for information needed for his important work to proceed

One of the finest autograph letters of Revere to reach the public market, his letters being noted rarities

Revere, recognized leader of the copper industry in the U.S., produces crucial bolts, sheets and other copper products needed to build the Navy’s first ships

This letter is unpublished, and we obtained...

One of the finest autograph letters of Revere to reach the public market, his letters being noted rarities

Revere, recognized leader of the copper industry in the U.S., produces crucial bolts, sheets and other copper products needed to build the Navy’s first ships

This letter is unpublished, and we obtained it from a descendant of the recipient, so it has never before been sold. A search of public sale records for the past decade shows only one minor Revere ALS having reached that market

As the Barbary Coast pirates continued to either break or try to renegotiate their treaties with the U.S. in the early 1790s, and with a war on in Europe, the U.S. found itself with no Navy, which proved to be an untenable position. Congress authorized the construction of six frigates at the cost of $688,888.82, which was signed into law March 27, 1794, by President Washington. Secretary of War Henry Knox wanted this fleet to be “equal, if not superior, to any frigates belonging to any of the European powers.”

Joshua Humphreys, a shipbuilder from Philadelphia who had turned merchant ships into warships during the Revolution, was chosen as the designer for America’s first Navy. Construction of the ships took place at several different seaports simultaneously: Norfolk, Va., Boston, New York, Philadelphia, Portsmouth, N.H., and Baltimore. The ships would be 20-feet longer than British ships and 13 feet longer than the 40-gun French frigates. A combination of white oak and live oak made up the 3-layered hull. The planks were held together with copper pins, along with 150,000 wooden pegs. This hardened external shell helped proved key, as cannon balls seemingly bounced off the planking, as with the USS Constitution, which earned her the nickname Old Ironsides for that reason. Three of the new ships would have 44 guns – Constitution, President and United States — and three would rate between 36 and 38 guns – Chesapeake, Congress and Constellation.

In late 1794, the Treasury ordered a large number of drawn copper bolts from England for the new Federal frigates being built. Because copper bolts would not corrode like iron, these were essential for fastening timbers that might come into contact with seawater. They were also important for ships whose hulls were sheathed in copper. Enter Paul Revere. Well known as a silversmith and engraver, his midnight ride is a legend and may have helped to start the Revolution. After the war his foundries were nothing short of revolutionary for the time. The firm of Revere and Son had been casting bells and cannon, and Paul Revere was approached by Navy Agent Henry Jackson who asked if he could reduce the oversized copper bolts received from England. According to Revere, “I then found out that it was necessary that bolts and spikes for ship building should be made out of malleable copper,” which was beyond the knowledge at the time. But Revere developed a process to do so. He resized copper bolts for the first ships in the United States Navy, thus allowing their construction to be successful.

But that was not the end of Revere’s contributions to the Navy. By 1800, Revere had discovered the secrets to rolling copper. He would produce the copper pins and any copper needed for hulls. That year, he became the first American to successfully roll copper into sheets for use as sheathing on naval vessels. By 1804 Paul Revere was the accredited head of the copper industry in the US.

The U.S. now had six ships. But 74 gun ships were a standard feature in European navies by 1800. That year six 74-gun ships were proposed to expand the U.S. Navy, and this was ordered by Congress and approved by President John Adams. Then Revere wrote to Navy Secretary Stoddert offering his array of copper products. In May 1800 Revere traveled to Philadelphia and received a contract to produce bolts and spikes for two ships being built in Boston and Portsmouth. Stoddert also asked Revere to refine some domestic ware and use it to roll sheet copper.

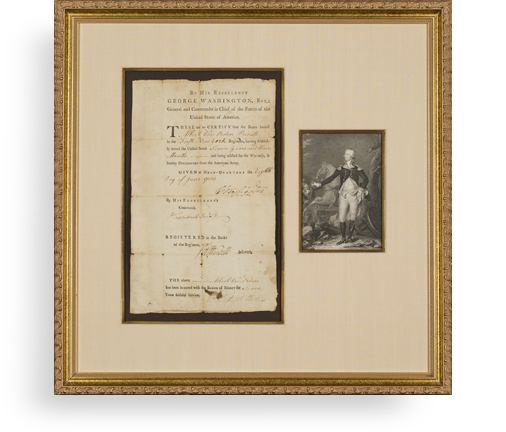

Autograph letter signed, Boston, June 8, 1800, to Joshua Humphreys, on the subject of producing copper products like bolts for the new 74-gun ships. “Mr. Higginson Naval Agent here has purchased the copper which Mr. Stoddert the Naval Secretary has directed him, & has delivered it [to] me. There is upwards of 500 lb., it is for making bolts, spikes etc. for the two seventy four gun ships which are to be built here and at Portsmouth. Would you be kind enough to write me the sizes of bolts & spikes, which you may think proper for building said ships, and what proportion of each. The Secretary directed me to apply to you for the sizes, etc. The sooner I have them the sooner I shall be able to fulfill my contract.

“That this may meet you and family in as good health as it leaves me is the wish of…Paul Revere.” The address leaf in his hand is still present, with an apparent docket by Humphreys.” The Higginson mentioned was Stephen Higginson, Boston ship maker and merchant. Stoddert was Benjamin Stoddert, Secretary of the Navy under John Adams. When Thomas Jefferson became president, he postponed construction of the 74 gun ships. Their production would have to wait until the War of 1812.

This letter is an extraordinary rarity, and is our first ever Revere letter. It is unpublished, and we obtained it from a descendant of the recipient, so it has never before been sold. A search of public sale records for the past decade shows only one Revere ALS having reached that market, and it had nothing to do with the Navy or Revolution, the two things for which Revere is most famous. Truly an American treasure.

Frame, Display, Preserve

Each frame is custom constructed, using only proper museum archival materials. This includes:The finest frames, tailored to match the document you have chosen. These can period style, antiqued, gilded, wood, etc. Fabric mats, including silk and satin, as well as museum mat board with hand painted bevels. Attachment of the document to the matting to ensure its protection. This "hinging" is done according to archival standards. Protective "glass," or Tru Vue Optium Acrylic glazing, which is shatter resistant, 99% UV protective, and anti-reflective. You benefit from our decades of experience in designing and creating beautiful, compelling, and protective framed historical documents.

Learn more about our Framing Services