Thomas Edison Wants to Be Sure There Are Enough Castings to Produce His Improved Phonograph

He writes his chief assistant, John Kruesi, asking about the brass castings on hand, and announces he intends to close his foundry

- Currency:

- USD

- GBP

- JPY

- EUR

- CNY

Edison also looks for help in creating his mining operation, asking for carpenters

John Kruesi apprenticed as a locksmith in Switzerland, and migrated to the United States where he settled in Newark, New Jersey. There he met Thomas Edison, who was impressed with the young Swiss immigrant and took a liking to...

Edison also looks for help in creating his mining operation, asking for carpenters

John Kruesi apprenticed as a locksmith in Switzerland, and migrated to the United States where he settled in Newark, New Jersey. There he met Thomas Edison, who was impressed with the young Swiss immigrant and took a liking to him, employing him in his workshop starting in 1872. He became Edison’s head machinist through his Newark and Menlo Park periods, responsible for translating Edison’s numerous rough sketches into working devices. Since constructing and testing models was central to Edison’s method of inventing, Kruesi’s skill in doing this was critical to Edison’s success as an inventor. By the late 1880s, Kruesi was General Manager of the Edison Machine Works, a company set up to produce dynamos, large electric motors, and other components of electrical illumination. In 1889 the Machine Works business moved to Schenectady, NY. However Kruesi was still assisting Edison in a variety of other projects, and Edison was hoping to get him back from Schenectady to New Jersey where Edison himself was located.

One of these projects was the phonograph, one of the greatest inventions of the 19th century. Invented and patented in 1877, the Edison Phonograph Company was formed on October 8, 1887, to market Edison’s machine. He introduced the Improved Phonograph by May of 1888, shortly followed by the Perfected Phonograph. The first wax cylinders Edison used were white and made of ceresin, beeswax, and stearic wax. The machine used metal castings for a number of functions. The phenomenal growth of the brass and copper industries at that time was due to the rapid and increasing demand because of the phonograph, telephone, electric light, electric motor, and most of Edison’s basic inventions. Edison recognized the necessity of pure quality metal for his products. and we learn here that he thought for a while that he could produce these cheaper and better himself. He experimented with operating a brass foundry, but closed it.

in 1891, Edison developed an enormous complex of mines, crushers, separators, and subsidiary buildings that came to be known as “The Works of the New Jersey and Pennsylvania Concentrating Company.” Kruesi had an interest in the company. This company produced briquettes of concentrated iron ore. The plant finally closed, never to reopen, on September 30, 1900. In its highest level of activity, the plant employed nearly 500 men.

In 1892, Edison determined that he needed carpenters for the mining operation, and he turned to Kruesi for help. Autograph letter signed, on New Jersey and Pennsylvania Concentrating Works letterhead, Ogden, N.J., no date but the year is 1892, to Kruesi. “We want carpenters, we pay from $2 to 2.50. Can’t you ask Langdon at Peterboro if he can send us some – want dozen.” He adds a PS showing him closing the foundry while at the same time assuring himself that there were sufficient castings for the phonographs: “Are we to get anymore castings at phonograph works? If not would like to know ahead so we can shut down brass foundry permanently. Answer to Orange [NJ]. Edison.” Apparently it was cheaper to buy the castings elsewhere, with no loss of quality.

We obtained this letter from the Kruesi descendants, and it has never before been offered for sale.

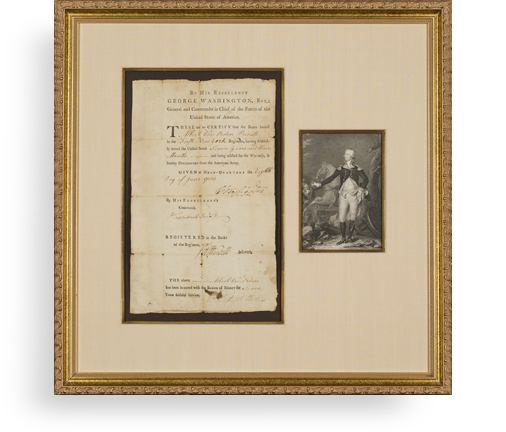

Frame, Display, Preserve

Each frame is custom constructed, using only proper museum archival materials. This includes:The finest frames, tailored to match the document you have chosen. These can period style, antiqued, gilded, wood, etc. Fabric mats, including silk and satin, as well as museum mat board with hand painted bevels. Attachment of the document to the matting to ensure its protection. This "hinging" is done according to archival standards. Protective "glass," or Tru Vue Optium Acrylic glazing, which is shatter resistant, 99% UV protective, and anti-reflective. You benefit from our decades of experience in designing and creating beautiful, compelling, and protective framed historical documents.

Learn more about our Framing Services